If you’re looking up how to reduce heating costs in warehouses, you’re probably dealing with the same daily reality as most facilities teams: big open space, high ceilings, constant door movement, and a heating system that works hard but still leaves cold spots.

The fix is rarely “turn it down and hope for the best”. The real wins come from matching the right heating approach to how a warehouse behaves, stopping heat escaping through doors, tightening up controls, and keeping equipment running at peak efficiency.

This guide breaks down the practical steps, using examples from the Reznor UK range so you can map improvements to real solutions.

1) Start with the two questions that decide your costs

Before you change anything, get clear on:

- Where do people actually need warmth?

Pick faces, packing benches, goods-in, despatch, pedestrian lanes.

- Where is heat being wasted?

Doorways, unsealed docks, warm air trapped at roof level, heating running outside occupancy.

Even a quick walkthrough on a cold morning will show you the patterns. Once you can see the problem areas, you can choose fixes that cut spend without punishing comfort.

2) Radiant vs warm air heating: choose the right “type” of heat

This is usually the biggest lever when you’re working out how to reduce heating costs in warehouses.

Warm air unit heaters: strong for whole-area comfort

Warm air heating is a solid option when you want a broadly consistent temperature across a large space, especially where airflow can be managed.

Reznor’s warm air unit heaters are designed for industrial and commercial buildings, with a focus on energy efficiency, performance, and reduced operating and life cycle costs. That category also highlights up to 35% energy saving on replacement heaters (RHeco units), plus easy installation and maintenance.

A few warm air options to know:

- Electric, gas-free alternative: e+ Electric Warm Air Unit Heaters offer instant start-up and adaptive control that continually monitors output to maintain room temperature efficiently. They also support “fan only” mode for air circulation in warmer months.

- Latest generation gas-fired: PHOTON Warm Air Heaters are designed for high efficiency and long-term cost benefits, with a modulating burner fitted as standard.

- Ultra-efficient condensing: RHeco Warm Air Heaters are built for low carbon buildings or organisations focused on reducing emissions, with thermal efficiencies up to 109% at minimum load and strong heat distribution.

- Cabinet heaters for large spaces (floor standing): if your warehouse needs a robust, dependable heater at ground level, COMET+ cabinet heaters are a cost-effective heating solution for many large industrial spaces. High efficiency condensing versions are available for natural gas fired models, with combustion efficiencies up to 94%, and options for free-blowing applications or use with ductwork.

Where warm air shines:

- Warehouses aiming for overall ambient comfort, with decent control over drafts and door infiltration.

Radiant heaters: targeted warmth, less heat wasted in the roof space

Radiant heating is often the better choice where you’re battling high ceilings, frequent door openings, or high air change. Rather than trying to heat the entire air volume, radiant systems focus heat where it matters, helping reduce wasted energy.

Reznor’s radiant heaters deliver targeted coverage by directly heating objects and people, and are designed for large spaces like warehousing, factories, and workshops. In addition, they can support efficiency improvements, including thermal efficiencies increased by up to 90% (range dependent).

Key radiant options include:

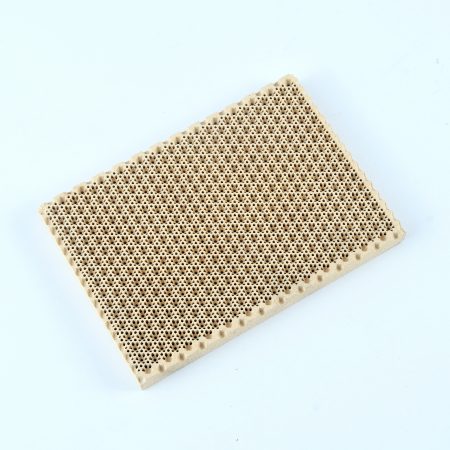

- Flexible zonal heating for large buildings: Vision Overhead Radiant U-Tube Heaters focus warmth on areas directly beneath, helping avoid heating unused zones such as ceiling level and high storage.

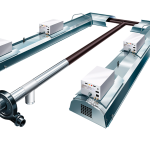

- Continuous, uniform coverage: Nor-Ray-Vac Continuous Radiant Heaters are designed to provide uniform heat over the floor area, with the option to create distinct zones for different comfort levels.

- Bespoke continuous system: Sonning2 OHA Continuous Radiant Heaters are designed specifically around the building and can support large-scale, high-level installations.

Where radiant shines:

- High bay warehouses, busy loading environments, and spaces where you want warmth at working level without “paying to heat the roof”.

Air to Air Heat Pumps: a future proof, gas-free path

If you’re planning beyond the next winter, it’s worth looking at heat pumps as part of a longer-term strategy, especially where decarbonisation targets or site electrification are on the roadmap.

The LIRA industrial air-to-air heat pump is a gas-free heating and cooling solution for industrial buildings, including warehouses, with year-round comfort focused on sustainability and efficiency. It’s designed for European climates and continues operating reliably even at -20°C. Being an air-to-air heat pump, direct heat is exchanged between outdoor and indoor units via refrigerant, which maximises the efficiency of both heating and cooling modes, and means no water circuit is needed.

3) Heat loss through doors: stop the leak that never shows up on a meter

Loading bays and shutter doors are one of the biggest silent drains on heating budgets. Every time a door opens, warm air leaves and cold air rushes in. If that happens dozens of times per hour, your heating system ends up constantly recovering.

Practical steps that usually make an immediate difference:

- Reduce “open time”: tighten dock processes so doors are not held open while loads are organised.

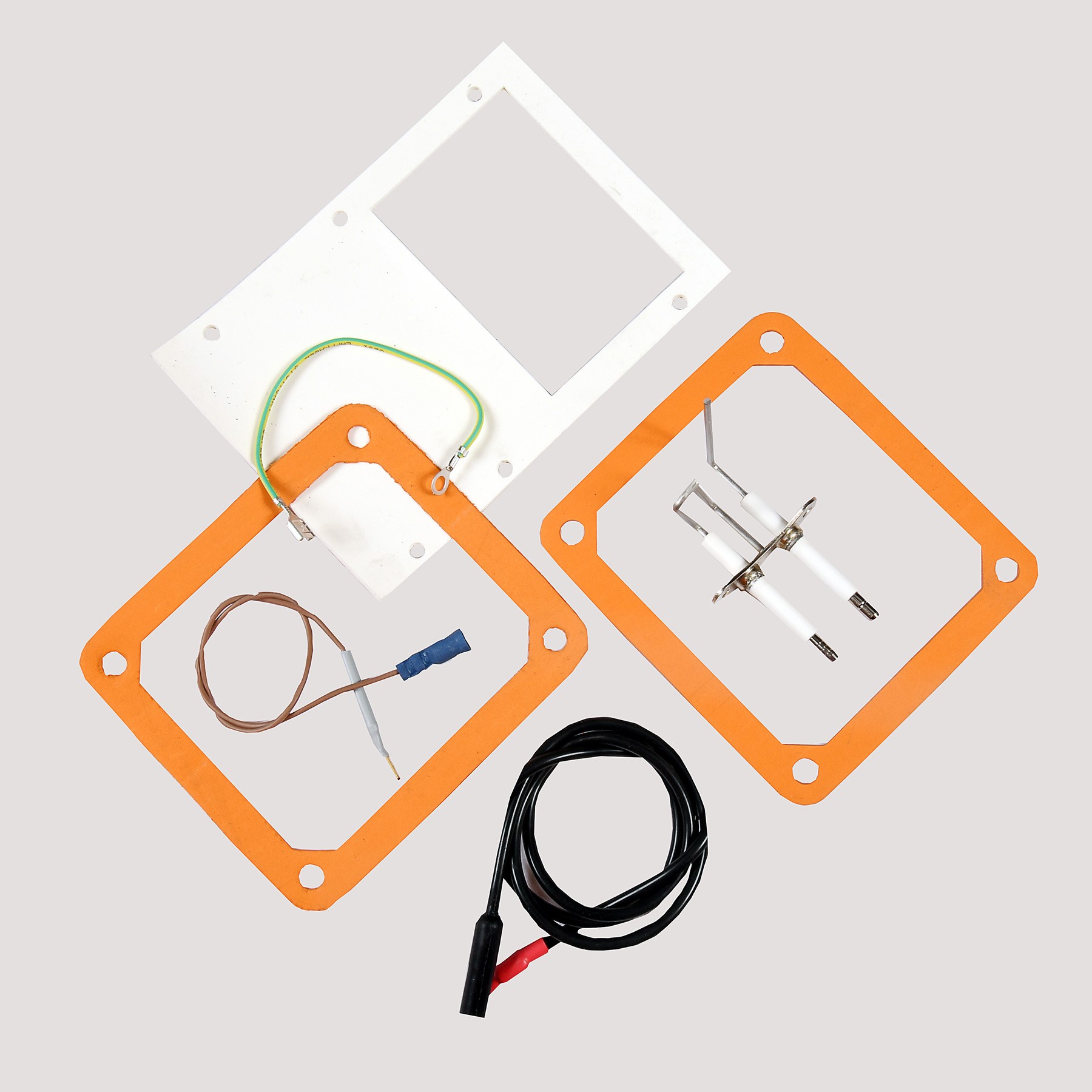

- Fix seals and gaps: worn gaskets and poor dock sealing leak heat even when doors are shut.

- Improve airflow planning: avoid aiming warm air straight at doors where it will exit the building.

- Use zonal heating in high-traffic areas: in many warehouses, it’s cheaper to maintain comfort where people work than to try to keep every cubic metre of air warm.

If doors are opening constantly, this is also where radiant heating can help, because targeted warmth is less affected by drafts and air exchange than heating the whole air volume.

Add air curtains for extra protection at entrances: air curtains support both radiant and warm air systems by creating a powerful down-flow of heated or ambient air at open doorways, helping reduce heat loss and the energy needed to recover temperature after every door cycle.

4) Smart controls and timers: heat when it’s needed, not when the building is empty

A warehouse can have the best heaters in the world and still overspend if the schedule is wrong.

Controls are where comfort and cost-saving can finally agree, because you’re not reducing temperature for the sake of it. You’re reducing waste.

High-impact control moves include:

- Start/stop scheduling aligned to shift patterns

- Setback temperatures overnight and during quiet periods

- Zoning so packing benches and pedestrian lanes stay comfortable without overheating storage aisles

- Locking sensible setpoints so the building stays consistent without constant manual tweaks

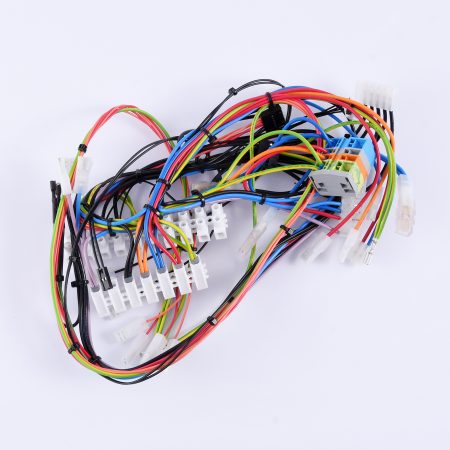

If you’re using SmartCom3, point teams to the SmartCom3 how-to videos playlist (labelled “SmartCom3 - How-to Videos”). It’s a handy way to tighten up programming, time/date settings, and heat modes without guesswork.

5) Maintenance best practices: protect efficiency all winter

This is the unglamorous part of how to reduce heating costs in warehouses, but it pays back every year. Poor maintenance increases energy use, creates uneven heating, and raises the risk of downtime when the weather turns.

A simple routine to keep things efficient:

- Pre-season checks: confirm fans, burners, and safety controls are operating correctly (as applicable).

- Keep airflow clear: blocked discharge paths and dusty components reduce performance and comfort.

- Re-check direction and throw: especially in high bay warehouses, a small change in angle can mean the difference between comfort at floor level and heat stuck overhead.

- Review layout changes: new racking, moved workstations, or changed processes can shift where heat is needed.

Warm air systems are designed with ease of installation and maintenance in mind, which is exactly what you want when you’re planning for reliable winter operation.

The takeaway: comfort stays, waste goes

Reducing warehouse heating costs is not about making the building colder. It’s about making heating more precise.

If you want a sensible path to follow:

- Pick the right heat delivery method (warm air vs radiant).

- Stop heat escaping through doors and docks.

- Tighten controls so you only heat what’s occupied, when it’s occupied.

- Keep maintenance predictable so efficiency does not drift.

If you want help matching the best option to your building layout, usage patterns, and ceiling height, book a free site survey today.

Book A Free Site Survey

Book A Free Site Survey